Smart planning support for skidding routes takes shape

Decision support

To make felling more time-efficient and low-impact, researchers have developed a tool that shows where the forestry machine's basic routes should go. Now a Mistra Digital Forest project is taking the next step and expanding the tool to also provide support for skidding routes.

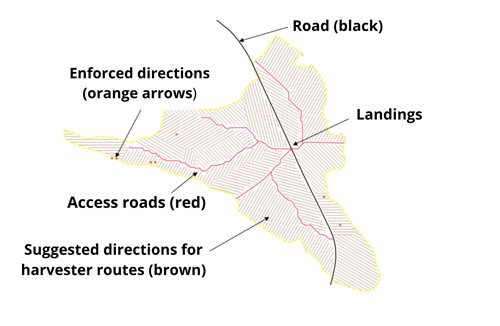

Based on data about where the timber is in the forest, and what the terrain looks like, it is possible to suggest where the forestry machine's basic routes - that is the main roads - should go when felling. Skogforsk has developed this kind of decision support, and various versions of it are now available on the market. Mistra Digital Forest researchers are currently taking the next step and developing a method that also suggests the skidding routes - temporary or permanent roads used to transport timber from the felling area to an access road or storage area – which are needed to reach all the trees during felling.

– Where the skidding routes will go is always a decision that is made in real time. It is a tough cognitive job for the machine operator, many decisions have to be made in a tight time-frame, all through their shift. By the end of the project, we want planning support that unburdens the operator. Instead of suggesting exactly how the skidding routes should go, it divides the area into different sections, and suggests the direction of flow from each section to the access road, says Rikard Lundqvist, project manager at Skogforsk.

Lower costs and less incidence of driving damage

A prototype will be ready in 2025 and, just like the decision support for access roads, it will take the slope of the terrain into account. Where there is an incline, the suggestion will always entail the forestry machine travelling in the direction of the slope, not along it, as this increases the risk of the machine tipping over. The model is trained on terrain maps supplemented with soil moisture maps. This second set of maps can also be used to assess where there is a risk of rutting, which can lead to ground damage.

The project is currently collecting data. Södra and SCA are selecting data from a total of 40 areas where teams with extensive experience have plotted the skidding routes manually.

– We hope to be able to add this function as another layer in the decision support tools we are currently using. This would mean that we could reduce the time and the cost of harvesting, but also reduce the incidence of driving damage. Having a smart strategy when opening up an area is something that comes with experience. At the same time, we have a shortage of operators and all the available resources are needed. Having driver support that helps relatively newly trained drivers to get to grips with the work is a necessity, says Thomas Persson, Business Developer at SCA.

Solution close to application

The operators in the selected teams have been interviewed about their strategies and the kind of instructions they need in order to do a good job. The idea is that the model will mimic the “mindset” of the experienced operators, and later in the project the forest operators will also assess and test the model's suggestions.

– Since we already have the tool for access roads in place, we are not starting from a blank sheet of paper. This means that we will probably get to the application stage considerably faster, concludes Rikard Lundqvist.